Page Summary

-

The job shop scheduling problem involves optimizing the allocation of machines to tasks within multiple jobs to minimize the total completion time (makespan).

-

Tasks have precedence constraints (must be completed in order) and machine exclusivity constraints (only one task per machine at a time).

-

Constraint programming is used to model the problem, defining variables for task start times and adding constraints to enforce precedence and prevent overlapping.

-

A constraint solver finds the optimal schedule by minimizing the makespan, adhering to the defined constraints.

-

The solution provides the start and end times for each task, offering an efficient schedule for job completion.

One common scheduling problem is the job shop, in which multiple jobs are processed on several machines.

Each job consists of a sequence of tasks, which must be performed in a given

order, and each task must be processed on a specific machine.

For example, the job could be the manufacture of a single consumer item, such as

an automobile.

The problem is to schedule the tasks on the machines so as to minimize the

length of the schedule—the time it takes for all the jobs to be completed.

There are several constraints for the job shop problem:

- No task for a job can be started until the previous task for that job is completed.

- A machine can only work on one task at a time.

- A task, once started, must run to completion.

Example Problem

Below is a simple example of a job shop problem, in which each task is labeled by a pair of numbers (m, p) where m is the number of the machine the task must be processed on and p is the processing time of the task — the amount of time it requires. (The numbering of jobs and machines starts at 0.)

- job 0 = [(0, 3), (1, 2), (2, 2)]

- job 1 = [(0, 2), (2, 1), (1, 4)]

- job 2 = [(1, 4), (2, 3)]

In the example, job 0 has three tasks. The first, (0, 3), must be processed on machine 0 in 3 units of time. The second, (1, 2), must be processed on machine 1 in 2 units of time, and so on. Altogether, there are eight tasks.

A solution for the problem

A solution to the job shop problem is an assignment of a start time for each

task, which meets the constraints given above.

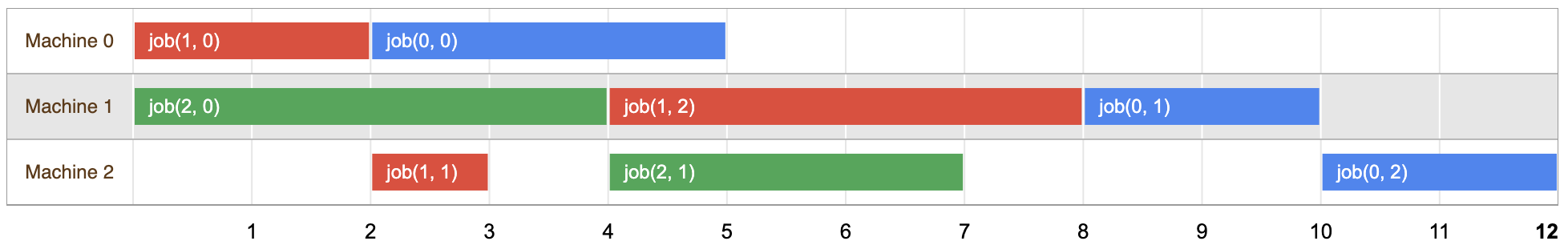

The diagram below shows one possible solution for the problem:

You can check that the tasks for each job are scheduled at non-overlapping time intervals, in the order given by the problem.

The length of this solution is 12, which is the first time when all three jobs are complete. However, as you will see below, this is not the optimal solution to the problem.

Variables and constraints for the problem

This section describes how to set up the variables and constraints for the

problem.

First, let task(i, j) denote the jth task in the sequence for job i. For

example, task(0, 2) denotes the second task for job 0, which corresponds to

the pair (1, 2) in the problem description.

Next, define ti, j to be the start time for task(i, j). The

ti, j are the variables in the job shop problem. Finding a

solution involves determining values for these variables that meet the

requirement of the problem.

There are two types of constraints for the job shop problem:

- Precedence constraints — These arise from the condition that for any

two consecutive tasks in the same job, the first must be completed before the

second can be started. For example,

task(0, 2)andtask(0, 3)are consecutive tasks for job 0. Since the processing time fortask(0, 2)is 2, the start time fortask(0, 3)must be at least 2 units of time after the start time for task 2. (Perhaps task 2 is painting a door, and it takes two hours for the paint to dry.) As a result, you get the following constraint:t0, 2 + 2 <=t0, 3

- No overlap constraints — These arise from the restriction that a

machine can't work on two tasks at the same time.

For example, task(0, 2) and task(2, 1) are both processed on machine 1.

Since their processing times are 2 and 4, respectively, one of the following

constraints must hold:

t0, 2 + 2 <=t2, 1 (iftask(0, 2)is scheduled beforetask(2, 1)) ort2, 1 + 4 <=t0, 2 (iftask(2, 1)is scheduled beforetask(0, 2)).

Objective for the problem

The objective of the job shop problem is to minimize the makespan: the length of time from the earliest start time of the jobs to the latest end time.

A Program solution

The following sections describe the main elements of a program that solves the job shop problem.

Import the libraries

The following code imports the required library.

Python

import collections from ortools.sat.python import cp_model

C++

#include <stdlib.h> #include <algorithm> #include <cstdint> #include <map> #include <numeric> #include <string> #include <tuple> #include <vector> #include "absl/base/log_severity.h" #include "absl/log/globals.h" #include "absl/strings/str_format.h" #include "ortools/base/init_google.h" #include "ortools/base/logging.h" #include "ortools/sat/cp_model.h" #include "ortools/sat/cp_model.pb.h" #include "ortools/sat/cp_model_solver.h"

Java

import static java.lang.Math.max; import com.google.ortools.Loader; import com.google.ortools.sat.CpModel; import com.google.ortools.sat.CpSolver; import com.google.ortools.sat.CpSolverStatus; import com.google.ortools.sat.IntVar; import com.google.ortools.sat.IntervalVar; import com.google.ortools.sat.LinearExpr; import java.util.ArrayList; import java.util.Arrays; import java.util.Collections; import java.util.Comparator; import java.util.HashMap; import java.util.List; import java.util.Map; import java.util.stream.IntStream;

C#

using System; using System.Collections; using System.Collections.Generic; using System.Linq; using Google.OrTools.Sat;

Define the data

Next, the program defines the data for the problem.

Python

jobs_data = [ # task = (machine_id, processing_time). [(0, 3), (1, 2), (2, 2)], # Job0 [(0, 2), (2, 1), (1, 4)], # Job1 [(1, 4), (2, 3)], # Job2 ] machines_count = 1 + max(task[0] for job in jobs_data for task in job) all_machines = range(machines_count) # Computes horizon dynamically as the sum of all durations. horizon = sum(task[1] for job in jobs_data for task in job)

C++

using Task = std::tuple<int64_t, int64_t>; // (machine_id, processing_time) using Job = std::vector<Task>; std::vector<Job> jobs_data = { {{0, 3}, {1, 2}, {2, 2}}, // Job_0: Task_0 Task_1 Task_2 {{0, 2}, {2, 1}, {1, 4}}, // Job_1: Task_0 Task_1 Task_2 {{1, 4}, {2, 3}}, // Job_2: Task_0 Task_1 }; int64_t num_machines = 0; for (const auto& job : jobs_data) { for (const auto& [machine, _] : job) { num_machines = std::max(num_machines, 1 + machine); } } std::vector<int> all_machines(num_machines); std::iota(all_machines.begin(), all_machines.end(), 0); // Computes horizon dynamically as the sum of all durations. int64_t horizon = 0; for (const auto& job : jobs_data) { for (const auto& [_, time] : job) { horizon += time; } }

Java

class Task { int machine; int duration; Task(int machine, int duration) { this.machine = machine; this.duration = duration; } } final List<List<Task>> allJobs = Arrays.asList(Arrays.asList(new Task(0, 3), new Task(1, 2), new Task(2, 2)), // Job0 Arrays.asList(new Task(0, 2), new Task(2, 1), new Task(1, 4)), // Job1 Arrays.asList(new Task(1, 4), new Task(2, 3)) // Job2 ); int numMachines = 1; for (List<Task> job : allJobs) { for (Task task : job) { numMachines = max(numMachines, 1 + task.machine); } } final int[] allMachines = IntStream.range(0, numMachines).toArray(); // Computes horizon dynamically as the sum of all durations. int horizon = 0; for (List<Task> job : allJobs) { for (Task task : job) { horizon += task.duration; } }

C#

var allJobs = new[] { new[] { // job0 new { machine = 0, duration = 3 }, // task0 new { machine = 1, duration = 2 }, // task1 new { machine = 2, duration = 2 }, // task2 } .ToList(), new[] { // job1 new { machine = 0, duration = 2 }, // task0 new { machine = 2, duration = 1 }, // task1 new { machine = 1, duration = 4 }, // task2 } .ToList(), new[] { // job2 new { machine = 1, duration = 4 }, // task0 new { machine = 2, duration = 3 }, // task1 } .ToList(), } .ToList(); int numMachines = 0; foreach (var job in allJobs) { foreach (var task in job) { numMachines = Math.Max(numMachines, 1 + task.machine); } } int[] allMachines = Enumerable.Range(0, numMachines).ToArray(); // Computes horizon dynamically as the sum of all durations. int horizon = 0; foreach (var job in allJobs) { foreach (var task in job) { horizon += task.duration; } }

Declare the model

The following code declares the model for the problem.

Python

model = cp_model.CpModel()

C++

CpModelBuilder cp_model;

Java

CpModel model = new CpModel();

C#

CpModel model = new CpModel();

Define the variables

The following code defines the variables in the problem.

Python

# Named tuple to store information about created variables. task_type = collections.namedtuple("task_type", "start end interval") # Named tuple to manipulate solution information. assigned_task_type = collections.namedtuple( "assigned_task_type", "start job index duration" ) # Creates job intervals and add to the corresponding machine lists. all_tasks = {} machine_to_intervals = collections.defaultdict(list) for job_id, job in enumerate(jobs_data): for task_id, task in enumerate(job): machine, duration = task suffix = f"_{job_id}_{task_id}" start_var = model.new_int_var(0, horizon, "start" + suffix) end_var = model.new_int_var(0, horizon, "end" + suffix) interval_var = model.new_interval_var( start_var, duration, end_var, "interval" + suffix ) all_tasks[job_id, task_id] = task_type( start=start_var, end=end_var, interval=interval_var ) machine_to_intervals[machine].append(interval_var)

C++

struct TaskType { IntVar start; IntVar end; IntervalVar interval; }; using TaskID = std::tuple<int, int>; // (job_id, task_id) std::map<TaskID, TaskType> all_tasks; std::map<int64_t, std::vector<IntervalVar>> machine_to_intervals; for (int job_id = 0; job_id < jobs_data.size(); ++job_id) { const auto& job = jobs_data[job_id]; for (int task_id = 0; task_id < job.size(); ++task_id) { const auto [machine, duration] = job[task_id]; std::string suffix = absl::StrFormat("_%d_%d", job_id, task_id); IntVar start = cp_model.NewIntVar({0, horizon}) .WithName(std::string("start") + suffix); IntVar end = cp_model.NewIntVar({0, horizon}) .WithName(std::string("end") + suffix); IntervalVar interval = cp_model.NewIntervalVar(start, duration, end) .WithName(std::string("interval") + suffix); TaskID key = std::make_tuple(job_id, task_id); all_tasks.emplace(key, TaskType{/*.start=*/start, /*.end=*/end, /*.interval=*/interval}); machine_to_intervals[machine].push_back(interval); } }

Java

class TaskType { IntVar start; IntVar end; IntervalVar interval; } Map<List<Integer>, TaskType> allTasks = new HashMap<>(); Map<Integer, List<IntervalVar>> machineToIntervals = new HashMap<>(); for (int jobID = 0; jobID < allJobs.size(); ++jobID) { List<Task> job = allJobs.get(jobID); for (int taskID = 0; taskID < job.size(); ++taskID) { Task task = job.get(taskID); String suffix = "_" + jobID + "_" + taskID; TaskType taskType = new TaskType(); taskType.start = model.newIntVar(0, horizon, "start" + suffix); taskType.end = model.newIntVar(0, horizon, "end" + suffix); taskType.interval = model.newIntervalVar( taskType.start, LinearExpr.constant(task.duration), taskType.end, "interval" + suffix); List<Integer> key = Arrays.asList(jobID, taskID); allTasks.put(key, taskType); machineToIntervals.computeIfAbsent(task.machine, (Integer k) -> new ArrayList<>()); machineToIntervals.get(task.machine).add(taskType.interval); } }

C#

Dictionary<Tuple<int, int>, Tuple<IntVar, IntVar, IntervalVar>> allTasks = new Dictionary<Tuple<int, int>, Tuple<IntVar, IntVar, IntervalVar>>(); // (start, end, duration) Dictionary<int, List<IntervalVar>> machineToIntervals = new Dictionary<int, List<IntervalVar>>(); for (int jobID = 0; jobID < allJobs.Count(); ++jobID) { var job = allJobs[jobID]; for (int taskID = 0; taskID < job.Count(); ++taskID) { var task = job[taskID]; String suffix = $"_{jobID}_{taskID}"; IntVar start = model.NewIntVar(0, horizon, "start" + suffix); IntVar end = model.NewIntVar(0, horizon, "end" + suffix); IntervalVar interval = model.NewIntervalVar(start, task.duration, end, "interval" + suffix); var key = Tuple.Create(jobID, taskID); allTasks[key] = Tuple.Create(start, end, interval); if (!machineToIntervals.ContainsKey(task.machine)) { machineToIntervals.Add(task.machine, new List<IntervalVar>()); } machineToIntervals[task.machine].Add(interval); } }

For each job and task, the program uses the model's

NewIntVar/new_int_var/newIntVar method to create the variables:

start_var: Start time of the task.end_var: End time of the task.

The upper bound for start_var and end_var is horizon, the sum of the

processing times for all tasks in all jobs.

horizon is sufficiently large to complete all tasks for the following reason:

if you schedule the tasks in non-overlapping time intervals (a non-optimal

solution), the total length of the schedule is exactly horizon. So the

duration of the optimal solution can't be any greater than horizon.

Next, the program uses the NewIntervalVar/new_interval_var/newIntervalVar

method to create an interval variable —whose value is a variable time

interval — for the task. The inputs to this method are:

- The start time of the task.

- The length of the time interval for the task.

- The end time of the task.

- The name for the interval variable.

In any solution, end_var minus start_var must equal duration.

Define the constraints

The following code defines the constraints for the problem.

Python

# Create and add disjunctive constraints. for machine in all_machines: model.add_no_overlap(machine_to_intervals[machine]) # Precedences inside a job. for job_id, job in enumerate(jobs_data): for task_id in range(len(job) - 1): model.add( all_tasks[job_id, task_id + 1].start >= all_tasks[job_id, task_id].end )

C++

// Create and add disjunctive constraints. for (const auto machine : all_machines) { cp_model.AddNoOverlap(machine_to_intervals[machine]); } // Precedences inside a job. for (int job_id = 0; job_id < jobs_data.size(); ++job_id) { const auto& job = jobs_data[job_id]; for (int task_id = 0; task_id < job.size() - 1; ++task_id) { TaskID key = std::make_tuple(job_id, task_id); TaskID next_key = std::make_tuple(job_id, task_id + 1); cp_model.AddGreaterOrEqual(all_tasks[next_key].start, all_tasks[key].end); } }

Java

// Create and add disjunctive constraints. for (int machine : allMachines) { List<IntervalVar> list = machineToIntervals.get(machine); model.addNoOverlap(list); } // Precedences inside a job. for (int jobID = 0; jobID < allJobs.size(); ++jobID) { List<Task> job = allJobs.get(jobID); for (int taskID = 0; taskID < job.size() - 1; ++taskID) { List<Integer> prevKey = Arrays.asList(jobID, taskID); List<Integer> nextKey = Arrays.asList(jobID, taskID + 1); model.addGreaterOrEqual(allTasks.get(nextKey).start, allTasks.get(prevKey).end); } }

C#

// Create and add disjunctive constraints. foreach (int machine in allMachines) { model.AddNoOverlap(machineToIntervals[machine]); } // Precedences inside a job. for (int jobID = 0; jobID < allJobs.Count(); ++jobID) { var job = allJobs[jobID]; for (int taskID = 0; taskID < job.Count() - 1; ++taskID) { var key = Tuple.Create(jobID, taskID); var nextKey = Tuple.Create(jobID, taskID + 1); model.Add(allTasks[nextKey].Item1 >= allTasks[key].Item2); } }

The program uses the model's AddNoOverlap/add_no_overlap/addNoOverlap method

to create the no overlap constraints, which prevent tasks for

the same machine from overlapping in time.

Next, the program adds the precedence constraints, which prevent consecutive tasks for the same job from overlapping in time. For each job and each task in the job, a linear constraint is added to specify that the end time of a task to occur before the start time of the next task in the job.

Define the objective

The following code defines the objective in the problem.

Python

# Makespan objective. obj_var = model.new_int_var(0, horizon, "makespan") model.add_max_equality( obj_var, [all_tasks[job_id, len(job) - 1].end for job_id, job in enumerate(jobs_data)], ) model.minimize(obj_var)

C++

// Makespan objective. IntVar obj_var = cp_model.NewIntVar({0, horizon}).WithName("makespan"); std::vector<IntVar> ends; for (int job_id = 0; job_id < jobs_data.size(); ++job_id) { const auto& job = jobs_data[job_id]; TaskID key = std::make_tuple(job_id, job.size() - 1); ends.push_back(all_tasks[key].end); } cp_model.AddMaxEquality(obj_var, ends); cp_model.Minimize(obj_var);

Java

// Makespan objective. IntVar objVar = model.newIntVar(0, horizon, "makespan"); List<IntVar> ends = new ArrayList<>(); for (int jobID = 0; jobID < allJobs.size(); ++jobID) { List<Task> job = allJobs.get(jobID); List<Integer> key = Arrays.asList(jobID, job.size() - 1); ends.add(allTasks.get(key).end); } model.addMaxEquality(objVar, ends); model.minimize(objVar);

C#

// Makespan objective. IntVar objVar = model.NewIntVar(0, horizon, "makespan"); List<IntVar> ends = new List<IntVar>(); for (int jobID = 0; jobID < allJobs.Count(); ++jobID) { var job = allJobs[jobID]; var key = Tuple.Create(jobID, job.Count() - 1); ends.Add(allTasks[key].Item2); } model.AddMaxEquality(objVar, ends); model.Minimize(objVar);

This code creates an objective variable and constrains it to be the max of the end of all jobs.

Invoke the solver

The following code calls the solver.

Python

solver = cp_model.CpSolver() status = solver.solve(model)

C++

const CpSolverResponse response = Solve(cp_model.Build());

Java

CpSolver solver = new CpSolver(); CpSolverStatus status = solver.solve(model);

C#

CpSolver solver = new CpSolver(); CpSolverStatus status = solver.Solve(model); Console.WriteLine($"Solve status: {status}");

Display the results

The following code displays the results, including the optimal schedule and task intervals.

Python

if status == cp_model.OPTIMAL or status == cp_model.FEASIBLE: print("Solution:") # Create one list of assigned tasks per machine. assigned_jobs = collections.defaultdict(list) for job_id, job in enumerate(jobs_data): for task_id, task in enumerate(job): machine = task[0] assigned_jobs[machine].append( assigned_task_type( start=solver.value(all_tasks[job_id, task_id].start), job=job_id, index=task_id, duration=task[1], ) ) # Create per machine output lines. output = "" for machine in all_machines: # Sort by starting time. assigned_jobs[machine].sort() sol_line_tasks = "Machine " + str(machine) + ": " sol_line = " " for assigned_task in assigned_jobs[machine]: name = f"job_{assigned_task.job}_task_{assigned_task.index}" # add spaces to output to align columns. sol_line_tasks += f"{name:15}" start = assigned_task.start duration = assigned_task.duration sol_tmp = f"[{start},{start + duration}]" # add spaces to output to align columns. sol_line += f"{sol_tmp:15}" sol_line += "\n" sol_line_tasks += "\n" output += sol_line_tasks output += sol_line # Finally print the solution found. print(f"Optimal Schedule Length: {solver.objective_value}") print(output) else: print("No solution found.")

C++

if (response.status() == CpSolverStatus::OPTIMAL || response.status() == CpSolverStatus::FEASIBLE) { LOG(INFO) << "Solution:"; // create one list of assigned tasks per machine. struct AssignedTaskType { int job_id; int task_id; int64_t start; int64_t duration; bool operator<(const AssignedTaskType& rhs) const { return std::tie(this->start, this->duration) < std::tie(rhs.start, rhs.duration); } }; std::map<int64_t, std::vector<AssignedTaskType>> assigned_jobs; for (int job_id = 0; job_id < jobs_data.size(); ++job_id) { const auto& job = jobs_data[job_id]; for (int task_id = 0; task_id < job.size(); ++task_id) { const auto [machine, duration] = job[task_id]; TaskID key = std::make_tuple(job_id, task_id); int64_t start = SolutionIntegerValue(response, all_tasks[key].start); assigned_jobs[machine].push_back( AssignedTaskType{/*.job_id=*/job_id, /*.task_id=*/task_id, /*.start=*/start, /*.duration=*/duration}); } } // Create per machine output lines. std::string output = ""; for (const auto machine : all_machines) { // Sort by starting time. std::sort(assigned_jobs[machine].begin(), assigned_jobs[machine].end()); std::string sol_line_tasks = "Machine " + std::to_string(machine) + ": "; std::string sol_line = " "; for (const auto& assigned_task : assigned_jobs[machine]) { std::string name = absl::StrFormat( "job_%d_task_%d", assigned_task.job_id, assigned_task.task_id); // Add spaces to output to align columns. sol_line_tasks += absl::StrFormat("%-15s", name); int64_t start = assigned_task.start; int64_t duration = assigned_task.duration; std::string sol_tmp = absl::StrFormat("[%i,%i]", start, start + duration); // Add spaces to output to align columns. sol_line += absl::StrFormat("%-15s", sol_tmp); } output += sol_line_tasks + "\n"; output += sol_line + "\n"; } // Finally print the solution found. LOG(INFO) << "Optimal Schedule Length: " << response.objective_value(); LOG(INFO) << "\n" << output; } else { LOG(INFO) << "No solution found."; }

Java

if (status == CpSolverStatus.OPTIMAL || status == CpSolverStatus.FEASIBLE) { class AssignedTask { int jobID; int taskID; int start; int duration; // Ctor AssignedTask(int jobID, int taskID, int start, int duration) { this.jobID = jobID; this.taskID = taskID; this.start = start; this.duration = duration; } } class SortTasks implements Comparator<AssignedTask> { @Override public int compare(AssignedTask a, AssignedTask b) { if (a.start != b.start) { return a.start - b.start; } else { return a.duration - b.duration; } } } System.out.println("Solution:"); // Create one list of assigned tasks per machine. Map<Integer, List<AssignedTask>> assignedJobs = new HashMap<>(); for (int jobID = 0; jobID < allJobs.size(); ++jobID) { List<Task> job = allJobs.get(jobID); for (int taskID = 0; taskID < job.size(); ++taskID) { Task task = job.get(taskID); List<Integer> key = Arrays.asList(jobID, taskID); AssignedTask assignedTask = new AssignedTask( jobID, taskID, (int) solver.value(allTasks.get(key).start), task.duration); assignedJobs.computeIfAbsent(task.machine, (Integer k) -> new ArrayList<>()); assignedJobs.get(task.machine).add(assignedTask); } } // Create per machine output lines. String output = ""; for (int machine : allMachines) { // Sort by starting time. Collections.sort(assignedJobs.get(machine), new SortTasks()); String solLineTasks = "Machine " + machine + ": "; String solLine = " "; for (AssignedTask assignedTask : assignedJobs.get(machine)) { String name = "job_" + assignedTask.jobID + "_task_" + assignedTask.taskID; // Add spaces to output to align columns. solLineTasks += String.format("%-15s", name); String solTmp = "[" + assignedTask.start + "," + (assignedTask.start + assignedTask.duration) + "]"; // Add spaces to output to align columns. solLine += String.format("%-15s", solTmp); } output += solLineTasks + "%n"; output += solLine + "%n"; } System.out.printf("Optimal Schedule Length: %f%n", solver.objectiveValue()); System.out.printf(output); } else { System.out.println("No solution found."); }

C#

if (status == CpSolverStatus.Optimal || status == CpSolverStatus.Feasible) { Console.WriteLine("Solution:"); Dictionary<int, List<AssignedTask>> assignedJobs = new Dictionary<int, List<AssignedTask>>(); for (int jobID = 0; jobID < allJobs.Count(); ++jobID) { var job = allJobs[jobID]; for (int taskID = 0; taskID < job.Count(); ++taskID) { var task = job[taskID]; var key = Tuple.Create(jobID, taskID); int start = (int)solver.Value(allTasks[key].Item1); if (!assignedJobs.ContainsKey(task.machine)) { assignedJobs.Add(task.machine, new List<AssignedTask>()); } assignedJobs[task.machine].Add(new AssignedTask(jobID, taskID, start, task.duration)); } } // Create per machine output lines. String output = ""; foreach (int machine in allMachines) { // Sort by starting time. assignedJobs[machine].Sort(); String solLineTasks = $"Machine {machine}: "; String solLine = " "; foreach (var assignedTask in assignedJobs[machine]) { String name = $"job_{assignedTask.jobID}_task_{assignedTask.taskID}"; // Add spaces to output to align columns. solLineTasks += $"{name,-15}"; String solTmp = $"[{assignedTask.start},{assignedTask.start+assignedTask.duration}]"; // Add spaces to output to align columns. solLine += $"{solTmp,-15}"; } output += solLineTasks + "\n"; output += solLine + "\n"; } // Finally print the solution found. Console.WriteLine($"Optimal Schedule Length: {solver.ObjectiveValue}"); Console.WriteLine($"\n{output}"); } else { Console.WriteLine("No solution found."); }

The optimal schedule is shown below:

Optimal Schedule Length: 11

Machine 0: job_0_0 job_1_0

[0,3] [3,5]

Machine 1: job_2_0 job_0_1 job_1_2

[0,4] [4,6] [7,11]

Machine 2: job_1_1 job_0_2 job_2_1

[5,6] [6,8] [8,11]

Eagle-eyed readers examining machine 1 might wonder why job_1_2 was scheduled at time 7 instead of time 6. Both are valid solutions, but remember: the objective is to minimize the makespan. Moving job_1_2 earlier wouldn't reduce the makespan , so the two solutions are equal from the solver's perspective.

Entire program

Finally, here is the entire program for the job shop problem.

Python

"""Minimal jobshop example.""" import collections from ortools.sat.python import cp_model def main() -> None: """Minimal jobshop problem.""" # Data. jobs_data = [ # task = (machine_id, processing_time). [(0, 3), (1, 2), (2, 2)], # Job0 [(0, 2), (2, 1), (1, 4)], # Job1 [(1, 4), (2, 3)], # Job2 ] machines_count = 1 + max(task[0] for job in jobs_data for task in job) all_machines = range(machines_count) # Computes horizon dynamically as the sum of all durations. horizon = sum(task[1] for job in jobs_data for task in job) # Create the model. model = cp_model.CpModel() # Named tuple to store information about created variables. task_type = collections.namedtuple("task_type", "start end interval") # Named tuple to manipulate solution information. assigned_task_type = collections.namedtuple( "assigned_task_type", "start job index duration" ) # Creates job intervals and add to the corresponding machine lists. all_tasks = {} machine_to_intervals = collections.defaultdict(list) for job_id, job in enumerate(jobs_data): for task_id, task in enumerate(job): machine, duration = task suffix = f"_{job_id}_{task_id}" start_var = model.new_int_var(0, horizon, "start" + suffix) end_var = model.new_int_var(0, horizon, "end" + suffix) interval_var = model.new_interval_var( start_var, duration, end_var, "interval" + suffix ) all_tasks[job_id, task_id] = task_type( start=start_var, end=end_var, interval=interval_var ) machine_to_intervals[machine].append(interval_var) # Create and add disjunctive constraints. for machine in all_machines: model.add_no_overlap(machine_to_intervals[machine]) # Precedences inside a job. for job_id, job in enumerate(jobs_data): for task_id in range(len(job) - 1): model.add( all_tasks[job_id, task_id + 1].start >= all_tasks[job_id, task_id].end ) # Makespan objective. obj_var = model.new_int_var(0, horizon, "makespan") model.add_max_equality( obj_var, [all_tasks[job_id, len(job) - 1].end for job_id, job in enumerate(jobs_data)], ) model.minimize(obj_var) # Creates the solver and solve. solver = cp_model.CpSolver() status = solver.solve(model) if status == cp_model.OPTIMAL or status == cp_model.FEASIBLE: print("Solution:") # Create one list of assigned tasks per machine. assigned_jobs = collections.defaultdict(list) for job_id, job in enumerate(jobs_data): for task_id, task in enumerate(job): machine = task[0] assigned_jobs[machine].append( assigned_task_type( start=solver.value(all_tasks[job_id, task_id].start), job=job_id, index=task_id, duration=task[1], ) ) # Create per machine output lines. output = "" for machine in all_machines: # Sort by starting time. assigned_jobs[machine].sort() sol_line_tasks = "Machine " + str(machine) + ": " sol_line = " " for assigned_task in assigned_jobs[machine]: name = f"job_{assigned_task.job}_task_{assigned_task.index}" # add spaces to output to align columns. sol_line_tasks += f"{name:15}" start = assigned_task.start duration = assigned_task.duration sol_tmp = f"[{start},{start + duration}]" # add spaces to output to align columns. sol_line += f"{sol_tmp:15}" sol_line += "\n" sol_line_tasks += "\n" output += sol_line_tasks output += sol_line # Finally print the solution found. print(f"Optimal Schedule Length: {solver.objective_value}") print(output) else: print("No solution found.") # Statistics. print("\nStatistics") print(f" - conflicts: {solver.num_conflicts}") print(f" - branches : {solver.num_branches}") print(f" - wall time: {solver.wall_time}s") if __name__ == "__main__": main()

C++

// Nurse scheduling problem with shift requests. #include <stdlib.h> #include <algorithm> #include <cstdint> #include <map> #include <numeric> #include <string> #include <tuple> #include <vector> #include "absl/base/log_severity.h" #include "absl/log/globals.h" #include "absl/strings/str_format.h" #include "ortools/base/init_google.h" #include "ortools/base/logging.h" #include "ortools/sat/cp_model.h" #include "ortools/sat/cp_model.pb.h" #include "ortools/sat/cp_model_solver.h" namespace operations_research { namespace sat { void MinimalJobshopSat() { using Task = std::tuple<int64_t, int64_t>; // (machine_id, processing_time) using Job = std::vector<Task>; std::vector<Job> jobs_data = { {{0, 3}, {1, 2}, {2, 2}}, // Job_0: Task_0 Task_1 Task_2 {{0, 2}, {2, 1}, {1, 4}}, // Job_1: Task_0 Task_1 Task_2 {{1, 4}, {2, 3}}, // Job_2: Task_0 Task_1 }; int64_t num_machines = 0; for (const auto& job : jobs_data) { for (const auto& [machine, _] : job) { num_machines = std::max(num_machines, 1 + machine); } } std::vector<int> all_machines(num_machines); std::iota(all_machines.begin(), all_machines.end(), 0); // Computes horizon dynamically as the sum of all durations. int64_t horizon = 0; for (const auto& job : jobs_data) { for (const auto& [_, time] : job) { horizon += time; } } // Creates the model. CpModelBuilder cp_model; struct TaskType { IntVar start; IntVar end; IntervalVar interval; }; using TaskID = std::tuple<int, int>; // (job_id, task_id) std::map<TaskID, TaskType> all_tasks; std::map<int64_t, std::vector<IntervalVar>> machine_to_intervals; for (int job_id = 0; job_id < jobs_data.size(); ++job_id) { const auto& job = jobs_data[job_id]; for (int task_id = 0; task_id < job.size(); ++task_id) { const auto [machine, duration] = job[task_id]; std::string suffix = absl::StrFormat("_%d_%d", job_id, task_id); IntVar start = cp_model.NewIntVar({0, horizon}) .WithName(std::string("start") + suffix); IntVar end = cp_model.NewIntVar({0, horizon}) .WithName(std::string("end") + suffix); IntervalVar interval = cp_model.NewIntervalVar(start, duration, end) .WithName(std::string("interval") + suffix); TaskID key = std::make_tuple(job_id, task_id); all_tasks.emplace(key, TaskType{/*.start=*/start, /*.end=*/end, /*.interval=*/interval}); machine_to_intervals[machine].push_back(interval); } } // Create and add disjunctive constraints. for (const auto machine : all_machines) { cp_model.AddNoOverlap(machine_to_intervals[machine]); } // Precedences inside a job. for (int job_id = 0; job_id < jobs_data.size(); ++job_id) { const auto& job = jobs_data[job_id]; for (int task_id = 0; task_id < job.size() - 1; ++task_id) { TaskID key = std::make_tuple(job_id, task_id); TaskID next_key = std::make_tuple(job_id, task_id + 1); cp_model.AddGreaterOrEqual(all_tasks[next_key].start, all_tasks[key].end); } } // Makespan objective. IntVar obj_var = cp_model.NewIntVar({0, horizon}).WithName("makespan"); std::vector<IntVar> ends; for (int job_id = 0; job_id < jobs_data.size(); ++job_id) { const auto& job = jobs_data[job_id]; TaskID key = std::make_tuple(job_id, job.size() - 1); ends.push_back(all_tasks[key].end); } cp_model.AddMaxEquality(obj_var, ends); cp_model.Minimize(obj_var); const CpSolverResponse response = Solve(cp_model.Build()); if (response.status() == CpSolverStatus::OPTIMAL || response.status() == CpSolverStatus::FEASIBLE) { LOG(INFO) << "Solution:"; // create one list of assigned tasks per machine. struct AssignedTaskType { int job_id; int task_id; int64_t start; int64_t duration; bool operator<(const AssignedTaskType& rhs) const { return std::tie(this->start, this->duration) < std::tie(rhs.start, rhs.duration); } }; std::map<int64_t, std::vector<AssignedTaskType>> assigned_jobs; for (int job_id = 0; job_id < jobs_data.size(); ++job_id) { const auto& job = jobs_data[job_id]; for (int task_id = 0; task_id < job.size(); ++task_id) { const auto [machine, duration] = job[task_id]; TaskID key = std::make_tuple(job_id, task_id); int64_t start = SolutionIntegerValue(response, all_tasks[key].start); assigned_jobs[machine].push_back( AssignedTaskType{/*.job_id=*/job_id, /*.task_id=*/task_id, /*.start=*/start, /*.duration=*/duration}); } } // Create per machine output lines. std::string output = ""; for (const auto machine : all_machines) { // Sort by starting time. std::sort(assigned_jobs[machine].begin(), assigned_jobs[machine].end()); std::string sol_line_tasks = "Machine " + std::to_string(machine) + ": "; std::string sol_line = " "; for (const auto& assigned_task : assigned_jobs[machine]) { std::string name = absl::StrFormat( "job_%d_task_%d", assigned_task.job_id, assigned_task.task_id); // Add spaces to output to align columns. sol_line_tasks += absl::StrFormat("%-15s", name); int64_t start = assigned_task.start; int64_t duration = assigned_task.duration; std::string sol_tmp = absl::StrFormat("[%i,%i]", start, start + duration); // Add spaces to output to align columns. sol_line += absl::StrFormat("%-15s", sol_tmp); } output += sol_line_tasks + "\n"; output += sol_line + "\n"; } // Finally print the solution found. LOG(INFO) << "Optimal Schedule Length: " << response.objective_value(); LOG(INFO) << "\n" << output; } else { LOG(INFO) << "No solution found."; } // Statistics. LOG(INFO) << "Statistics"; LOG(INFO) << CpSolverResponseStats(response); } } // namespace sat } // namespace operations_research int main(int argc, char* argv[]) { InitGoogle(argv[0], &argc, &argv, true); absl::SetStderrThreshold(absl::LogSeverityAtLeast::kInfo); operations_research::sat::MinimalJobshopSat(); return EXIT_SUCCESS; }

Java

package com.google.ortools.sat.samples; import static java.lang.Math.max; import com.google.ortools.Loader; import com.google.ortools.sat.CpModel; import com.google.ortools.sat.CpSolver; import com.google.ortools.sat.CpSolverStatus; import com.google.ortools.sat.IntVar; import com.google.ortools.sat.IntervalVar; import com.google.ortools.sat.LinearExpr; import java.util.ArrayList; import java.util.Arrays; import java.util.Collections; import java.util.Comparator; import java.util.HashMap; import java.util.List; import java.util.Map; import java.util.stream.IntStream; /** Minimal Jobshop problem. */ public class MinimalJobshopSat { public static void main(String[] args) { Loader.loadNativeLibraries(); class Task { int machine; int duration; Task(int machine, int duration) { this.machine = machine; this.duration = duration; } } final List<List<Task>> allJobs = Arrays.asList(Arrays.asList(new Task(0, 3), new Task(1, 2), new Task(2, 2)), // Job0 Arrays.asList(new Task(0, 2), new Task(2, 1), new Task(1, 4)), // Job1 Arrays.asList(new Task(1, 4), new Task(2, 3)) // Job2 ); int numMachines = 1; for (List<Task> job : allJobs) { for (Task task : job) { numMachines = max(numMachines, 1 + task.machine); } } final int[] allMachines = IntStream.range(0, numMachines).toArray(); // Computes horizon dynamically as the sum of all durations. int horizon = 0; for (List<Task> job : allJobs) { for (Task task : job) { horizon += task.duration; } } // Creates the model. CpModel model = new CpModel(); class TaskType { IntVar start; IntVar end; IntervalVar interval; } Map<List<Integer>, TaskType> allTasks = new HashMap<>(); Map<Integer, List<IntervalVar>> machineToIntervals = new HashMap<>(); for (int jobID = 0; jobID < allJobs.size(); ++jobID) { List<Task> job = allJobs.get(jobID); for (int taskID = 0; taskID < job.size(); ++taskID) { Task task = job.get(taskID); String suffix = "_" + jobID + "_" + taskID; TaskType taskType = new TaskType(); taskType.start = model.newIntVar(0, horizon, "start" + suffix); taskType.end = model.newIntVar(0, horizon, "end" + suffix); taskType.interval = model.newIntervalVar( taskType.start, LinearExpr.constant(task.duration), taskType.end, "interval" + suffix); List<Integer> key = Arrays.asList(jobID, taskID); allTasks.put(key, taskType); machineToIntervals.computeIfAbsent(task.machine, (Integer k) -> new ArrayList<>()); machineToIntervals.get(task.machine).add(taskType.interval); } } // Create and add disjunctive constraints. for (int machine : allMachines) { List<IntervalVar> list = machineToIntervals.get(machine); model.addNoOverlap(list); } // Precedences inside a job. for (int jobID = 0; jobID < allJobs.size(); ++jobID) { List<Task> job = allJobs.get(jobID); for (int taskID = 0; taskID < job.size() - 1; ++taskID) { List<Integer> prevKey = Arrays.asList(jobID, taskID); List<Integer> nextKey = Arrays.asList(jobID, taskID + 1); model.addGreaterOrEqual(allTasks.get(nextKey).start, allTasks.get(prevKey).end); } } // Makespan objective. IntVar objVar = model.newIntVar(0, horizon, "makespan"); List<IntVar> ends = new ArrayList<>(); for (int jobID = 0; jobID < allJobs.size(); ++jobID) { List<Task> job = allJobs.get(jobID); List<Integer> key = Arrays.asList(jobID, job.size() - 1); ends.add(allTasks.get(key).end); } model.addMaxEquality(objVar, ends); model.minimize(objVar); // Creates a solver and solves the model. CpSolver solver = new CpSolver(); CpSolverStatus status = solver.solve(model); if (status == CpSolverStatus.OPTIMAL || status == CpSolverStatus.FEASIBLE) { class AssignedTask { int jobID; int taskID; int start; int duration; // Ctor AssignedTask(int jobID, int taskID, int start, int duration) { this.jobID = jobID; this.taskID = taskID; this.start = start; this.duration = duration; } } class SortTasks implements Comparator<AssignedTask> { @Override public int compare(AssignedTask a, AssignedTask b) { if (a.start != b.start) { return a.start - b.start; } else { return a.duration - b.duration; } } } System.out.println("Solution:"); // Create one list of assigned tasks per machine. Map<Integer, List<AssignedTask>> assignedJobs = new HashMap<>(); for (int jobID = 0; jobID < allJobs.size(); ++jobID) { List<Task> job = allJobs.get(jobID); for (int taskID = 0; taskID < job.size(); ++taskID) { Task task = job.get(taskID); List<Integer> key = Arrays.asList(jobID, taskID); AssignedTask assignedTask = new AssignedTask( jobID, taskID, (int) solver.value(allTasks.get(key).start), task.duration); assignedJobs.computeIfAbsent(task.machine, (Integer k) -> new ArrayList<>()); assignedJobs.get(task.machine).add(assignedTask); } } // Create per machine output lines. String output = ""; for (int machine : allMachines) { // Sort by starting time. Collections.sort(assignedJobs.get(machine), new SortTasks()); String solLineTasks = "Machine " + machine + ": "; String solLine = " "; for (AssignedTask assignedTask : assignedJobs.get(machine)) { String name = "job_" + assignedTask.jobID + "_task_" + assignedTask.taskID; // Add spaces to output to align columns. solLineTasks += String.format("%-15s", name); String solTmp = "[" + assignedTask.start + "," + (assignedTask.start + assignedTask.duration) + "]"; // Add spaces to output to align columns. solLine += String.format("%-15s", solTmp); } output += solLineTasks + "%n"; output += solLine + "%n"; } System.out.printf("Optimal Schedule Length: %f%n", solver.objectiveValue()); System.out.printf(output); } else { System.out.println("No solution found."); } // Statistics. System.out.println("Statistics"); System.out.printf(" conflicts: %d%n", solver.numConflicts()); System.out.printf(" branches : %d%n", solver.numBranches()); System.out.printf(" wall time: %f s%n", solver.wallTime()); } private MinimalJobshopSat() {} }

C#

using System; using System.Collections; using System.Collections.Generic; using System.Linq; using Google.OrTools.Sat; public class ScheduleRequestsSat { private class AssignedTask : IComparable { public int jobID; public int taskID; public int start; public int duration; public AssignedTask(int jobID, int taskID, int start, int duration) { this.jobID = jobID; this.taskID = taskID; this.start = start; this.duration = duration; } public int CompareTo(object obj) { if (obj == null) return 1; AssignedTask otherTask = obj as AssignedTask; if (otherTask != null) { if (this.start != otherTask.start) return this.start.CompareTo(otherTask.start); else return this.duration.CompareTo(otherTask.duration); } else throw new ArgumentException("Object is not a Temperature"); } } public static void Main(String[] args) { var allJobs = new[] { new[] { // job0 new { machine = 0, duration = 3 }, // task0 new { machine = 1, duration = 2 }, // task1 new { machine = 2, duration = 2 }, // task2 } .ToList(), new[] { // job1 new { machine = 0, duration = 2 }, // task0 new { machine = 2, duration = 1 }, // task1 new { machine = 1, duration = 4 }, // task2 } .ToList(), new[] { // job2 new { machine = 1, duration = 4 }, // task0 new { machine = 2, duration = 3 }, // task1 } .ToList(), } .ToList(); int numMachines = 0; foreach (var job in allJobs) { foreach (var task in job) { numMachines = Math.Max(numMachines, 1 + task.machine); } } int[] allMachines = Enumerable.Range(0, numMachines).ToArray(); // Computes horizon dynamically as the sum of all durations. int horizon = 0; foreach (var job in allJobs) { foreach (var task in job) { horizon += task.duration; } } // Creates the model. CpModel model = new CpModel(); Dictionary<Tuple<int, int>, Tuple<IntVar, IntVar, IntervalVar>> allTasks = new Dictionary<Tuple<int, int>, Tuple<IntVar, IntVar, IntervalVar>>(); // (start, end, duration) Dictionary<int, List<IntervalVar>> machineToIntervals = new Dictionary<int, List<IntervalVar>>(); for (int jobID = 0; jobID < allJobs.Count(); ++jobID) { var job = allJobs[jobID]; for (int taskID = 0; taskID < job.Count(); ++taskID) { var task = job[taskID]; String suffix = $"_{jobID}_{taskID}"; IntVar start = model.NewIntVar(0, horizon, "start" + suffix); IntVar end = model.NewIntVar(0, horizon, "end" + suffix); IntervalVar interval = model.NewIntervalVar(start, task.duration, end, "interval" + suffix); var key = Tuple.Create(jobID, taskID); allTasks[key] = Tuple.Create(start, end, interval); if (!machineToIntervals.ContainsKey(task.machine)) { machineToIntervals.Add(task.machine, new List<IntervalVar>()); } machineToIntervals[task.machine].Add(interval); } } // Create and add disjunctive constraints. foreach (int machine in allMachines) { model.AddNoOverlap(machineToIntervals[machine]); } // Precedences inside a job. for (int jobID = 0; jobID < allJobs.Count(); ++jobID) { var job = allJobs[jobID]; for (int taskID = 0; taskID < job.Count() - 1; ++taskID) { var key = Tuple.Create(jobID, taskID); var nextKey = Tuple.Create(jobID, taskID + 1); model.Add(allTasks[nextKey].Item1 >= allTasks[key].Item2); } } // Makespan objective. IntVar objVar = model.NewIntVar(0, horizon, "makespan"); List<IntVar> ends = new List<IntVar>(); for (int jobID = 0; jobID < allJobs.Count(); ++jobID) { var job = allJobs[jobID]; var key = Tuple.Create(jobID, job.Count() - 1); ends.Add(allTasks[key].Item2); } model.AddMaxEquality(objVar, ends); model.Minimize(objVar); // Solve CpSolver solver = new CpSolver(); CpSolverStatus status = solver.Solve(model); Console.WriteLine($"Solve status: {status}"); if (status == CpSolverStatus.Optimal || status == CpSolverStatus.Feasible) { Console.WriteLine("Solution:"); Dictionary<int, List<AssignedTask>> assignedJobs = new Dictionary<int, List<AssignedTask>>(); for (int jobID = 0; jobID < allJobs.Count(); ++jobID) { var job = allJobs[jobID]; for (int taskID = 0; taskID < job.Count(); ++taskID) { var task = job[taskID]; var key = Tuple.Create(jobID, taskID); int start = (int)solver.Value(allTasks[key].Item1); if (!assignedJobs.ContainsKey(task.machine)) { assignedJobs.Add(task.machine, new List<AssignedTask>()); } assignedJobs[task.machine].Add(new AssignedTask(jobID, taskID, start, task.duration)); } } // Create per machine output lines. String output = ""; foreach (int machine in allMachines) { // Sort by starting time. assignedJobs[machine].Sort(); String solLineTasks = $"Machine {machine}: "; String solLine = " "; foreach (var assignedTask in assignedJobs[machine]) { String name = $"job_{assignedTask.jobID}_task_{assignedTask.taskID}"; // Add spaces to output to align columns. solLineTasks += $"{name,-15}"; String solTmp = $"[{assignedTask.start},{assignedTask.start+assignedTask.duration}]"; // Add spaces to output to align columns. solLine += $"{solTmp,-15}"; } output += solLineTasks + "\n"; output += solLine + "\n"; } // Finally print the solution found. Console.WriteLine($"Optimal Schedule Length: {solver.ObjectiveValue}"); Console.WriteLine($"\n{output}"); } else { Console.WriteLine("No solution found."); } Console.WriteLine("Statistics"); Console.WriteLine($" conflicts: {solver.NumConflicts()}"); Console.WriteLine($" branches : {solver.NumBranches()}"); Console.WriteLine($" wall time: {solver.WallTime()}s"); } }